What you need

Materials:

• ¾” PVC Pipe ~ 10 ft.

• ½” PVC Pipe ~ 17 ft.

• (14) ¾” PVC Tees

• (12) ¾” to ½” PVC Bushings

• (2) ¾” PVC Elbows

• (4) ¾” PVC Caps (optional)

• 1-1/2” Yards of Fabric

• 2 Suction Cup Hooks

• Sewing Materials

Instructions

My yearly holiday gift wrapping routine usually goes as follows: First, I dig through every closet looking for where I stashed the unruly grocery bag full of last year’s wrapping paper. Next I search every drawer looking for the “good” set of scissors. After that I dump out the grocery bag of paper and hope to find a left over roll of tape. Once I finally scrounge up all the materials and get the gift wrapped, I throw everything back into the grocery bag and stash it back into whatever closet has room. Whew!

Sound familiar? Maybe your gift wrapping experiences aren’t as stressful as mine. Even so, gift wrap is usually one of the last things people make time to organize as the holiday season rolls around. This year I decided I’d had enough, so I put my ingenuity and some PVC pipe to work in designing a gift wrapping station I could use all year round.

I decided to use PVC pipe to build the frame since it’s cheap, easy to work with and happens to be easy for me to procure (I work for an industrial PVC supplier). The design I created holds six rolls of wrapping paper (30” length rolls) on rungs and includes a place to store scissors, tape, ribbon etc. It also has a pouch for storing all those extra rolls you don’t use very often. The final result was fantastic! I can easily pull out and cut the length of paper I need, and it kind of feels like I have my own little gift boutique. Want to make one of your own? Below are the step-by-step instructions to get your wrapping game organized once and for all!

Step One – Cut and Clean Pipe:

The first step is to cut your ½” and ¾” size pipe into the appropriate lengths. At the hardware store PVC pipe usually comes in 10 ft. lengths so keep that in mind when going to pick it up. To cut the pipe you can use an electric saw or PVC cutting tool (pictured here). It’s a good idea to measure and cut your longest pieces first to conserve your uncut pipe in case of a mistake. I highly recommend investing in a PVC pipe cutting tool. You can find economical versions at your local hardware store, and it will save you loads of frustration and elbow grease!

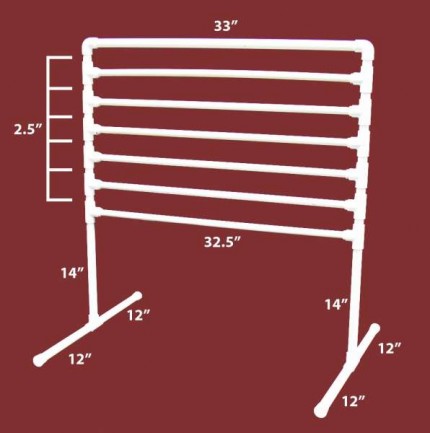

Check out the diagram below showing the lengths of pipe and number of pieces you’ll need of each. The outer frame is made of ¾” size PVC pipe, while the six horizontal rungs are made of ½” size pipe. I made these rungs smaller in diameter so they would be easier to fit through different styles of wrapping paper rolls. Note: this design is meant to accommodate rolls of paper that are 30” in length. For longer 36” rolls you can adjust the lengths of the rungs to fit.

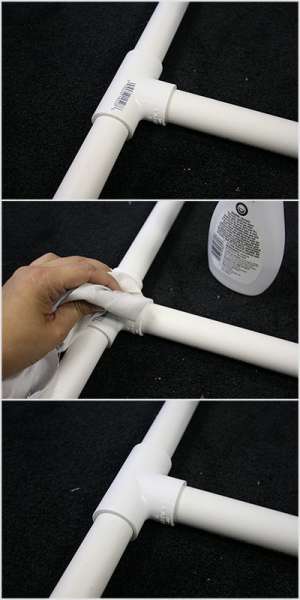

After your pieces are all cut, you can clean them for a nice polished look. Use some acetone (you can use acetone based nail polish remover) and a rag to polish off any manufacturer printing on the pipe. The acetone works to erode that top layer of dirt and ink on the pipe, leaving a nice and clean white surface. This also works for the barcodes on your PVC fittings! It’s also a good idea to sand down any rough edges you might have on the ends of pipe. This happens most noticeably when using a hand saw, but even small jagged edges can make it difficult to properly attach the pipe and fittings. Course grit sandpaper or a metal file work great for this.

Step Two – Fit together:

The next step is to fit all the pieces together. Do this before you try to put on your wrapping paper rolls. You’ll want to make sure all your pieces fit together correctly. To make it easy to take apart again, only press the parts together hard enough for them to stay put temporarily.

Check out the diagram below for where each piece goes. You can assemble the frame on the floor then add the legs, or assemble the legs and work up.

Most of the fittings used in this design are tees. These are used to create the stand as well as to hold up the six rungs. In order to fit the ½” size PVC pipe rungs into the ¾” size tees you’ll need to use a reducing bushing. You can find this size bushing (part number 437-101) for less than a quarter each at the store or online. This fitting makes a larger size fitting end into a smaller size (in this case ¾” to ½”). Press one bushing into 12 of the tees like so:

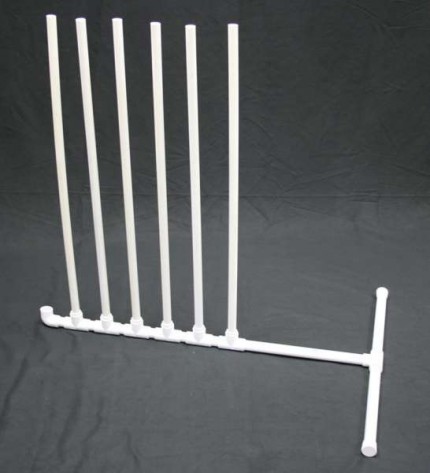

The other type of fitting used in this design is a ¾” elbow (part number 406-007). These are used at the very top of the frame to attach the ¾” rung. I also added a ¾” end cap to the bottom legs of the frame, but this is optional. It just makes for a slightly more finished look. Once everything is assembled the frame should end up looking like this:

The other type of fitting used in this design is a ¾” elbow (part number 406-007). These are used at the very top of the frame to attach the ¾” rung. I also added a ¾” end cap to the bottom legs of the frame, but this is optional. It just makes for a slightly more finished look. Once everything is assembled the frame should end up looking like this:

Step Three – Cut and Sew Organizer

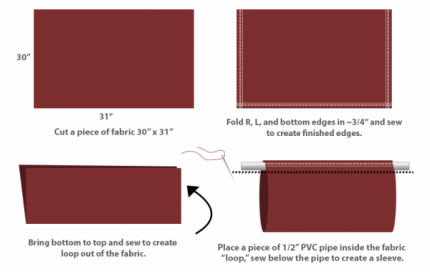

Next, we can start making the fabric organizer that will hang from the bottom rung. I’m no seamstress and don’t have a sewing machine, so I decided to use a new-sew heat bond tape to make mine. I started with a yard and a half of fabric to be safe. From that I cut a piece 30” x 31”. Next, turn the fabric backside up and fold the bottom, right, and left edges in about ¾”. Sew or bond these edges.

After that, bring the newly hemmed bottom up to meet the top of the fabric. We want to create a big fabric loop by sewing the bottom to the top. Put the hemmed edge over the raw top edge and sew.

Next, stick one of the ½” pipe pieces you cut through the loop and bring it to the top that you just sewed together. Pin and sew just below the pipe to make a sleeve around it (This is probably about 1-1/2” or 2” down from the top). See my diagram below for a better visual.

Once the main fabric loop and sleeve are sewn, measure out a few pieces of fabric for pockets. You can tweak this as you wish to accommodate your needs. For mine I measured out 8” x 8” for the pocket on the left and 13” x 9” for the larger pocket on the right. Fold in and sew the top raw edge to create a finished opening to the pocket (about ½”). Then fold in the other three sides and sew to one side of the fabric loop you created earlier. Again, I used new sew tape, so I ironed and bonded instead of sewed. If you have a sewing machine, this should be quick work.

Between the two pockets I wanted to have a place to hang ribbon or tape, so I bought a pack of suction cup hooks at the dollar store and attached them by cutting a small hole with scissors and then making notches around it large enough for the hook to fit through but not the suction cup. You can secure the hook by putting a few stitches through the fabric and plastic suction part. I wasn’t planning on hanging anything heavy so these worked perfectly.

Step Four – Add the organizer and Paper:

Once the fabric piece is complete we can put it all together! I found it easiest to take off one vertical side of the frame so all the rungs were detached and ready to slide the paper and fabric onto – sort of like the picture below.

Choose the six wrapping paper rolls you expect to use the most and slide them on one by one. You can always change these out later if you want. Last, thread the fabric organizer onto the bottom rung and attach the frame back on the other side. Pick the stand back upright and push all the PVC pieces together firmly.

That’s it! A custom-made wrapping station with room for your paper, scissors, tape, ribbon and more. I designed this station to hold extra rolls in the fabric “loop” below, since I know most people don’t keep exactly six rolls of paper in the house. I put paper I don’t use regularly (think baby shower or Bat Mitzvah) below so they are accessible, but not in the way of my most used rolls.

Get really creative and tweak the design to include more rolls, longer rolls, or extra storage. Please share your ideas for customizing or improving the design. This is just one way to organize! The final product of my design ended up measuring 35.5” wide, 37.5” tall, and 25.75” deep (on account of the legs). If you wanted to be really fancy you could even put casters on the bottom of the frame for easy moving. Luckily, the PVC frame makes the whole thing surprisingly lightweight yet sturdy enough to last me for years to come. No more gift wrapping mayhem for me!

About the project creator:

Amanda Hill is the Content Manager at CIS, an industrial supplier of PVC products, which includes pipe, fittings, valves and support products. Amanda spend’s a lot of time working with PVC products, creating DIY projects that showcase the many uses for PVC. With the holiday season fast approaching, these projects are of great use. Learn More by visiting us on Google+

nice idea, but if you had stuffed you wrapping supplies into whatever closet had room before, where do you plan to store this big bulky contraption now?

This project is fantastic! I want to make one for my ribbon collection. I have hundreds of ribbons all stashed in closets and drawers! When I can’t find ribbon I know I have I go out and buy more. This project will save me time, money and frustration!! Thanks